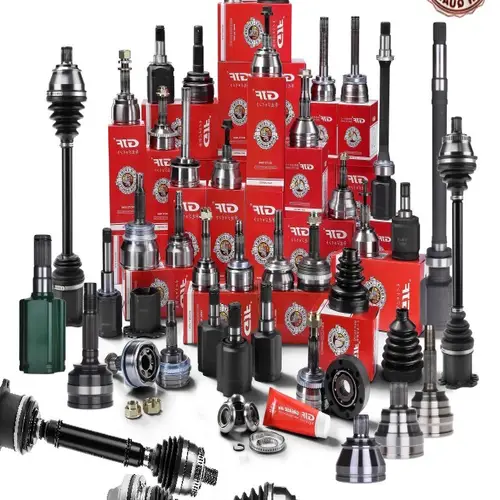

China Wholesaler 2% Off GJF Auto Spare Parts – Front CV Axle Drive Shaft, Inner CV Joint, Outer CV Joint for Honda and Mazda

Product Description

Warm Tips: Please Contact Us to Confirm Your Car Model

We offer a comprehensive range of auto spare parts including CV drive shafts, CV axles, CV joints, and CV boots. Our products are meticulously crafted using high-quality materials and undergo stringent quality control to ensure you receive the best performance and durability. With over 20 years of experience in the industry, we pride ourselves on catering to various markets globally and meeting diverse customer needs with our OEM/ODM services.

Product Details

| Product Name | CV JOINT | Material | 42CrMo alloy steel |

| Car Fitment | For Honda and Mazda | Warranty | 12 months |

| Model | Pls contact us for more details | Place of Origin | Zhangzhou, China |

| Certification | SGS/TUV/ISO | MOQ | 4 PCS |

| Transportation | Express/ by sea/ by air/ by land | Delivery Time | 1-7 days |

| OEM/ODM | Yes | Brand | GJF |

| Advantages | Large stocks/ deliver quickly/ strict quality supervision | Payment | L/C, T/T, Western Union, Cash, PayPal |

| Sample Service | Depends on the situation of stock | Weight | About 2-3KG |

Detailed Photos

Images coming soon…

Customer Reviews

Our customers have consistently provided us with positive reviews, praising the reliability and performance of our auto parts. These testimonials reinforce our commitment to delivering high-quality products that meet customer expectations.

Packaging & Shipping

Our products are securely packaged to prevent damage during transit. We offer various shipping options including express, sea, air, and land transport, ensuring your order reaches you promptly.

FAQ

- Q: What is the material used for the CV joints?

A: The CV joints are made of 42CrMo alloy steel. - Q: What is the warranty period for your products?

A: Our products come with a 12-month warranty. - Q: Can you provide OEM/ODM services?

A: Yes, we offer OEM/ODM services to meet your specific requirements. - Q: How long does delivery take?

A: Delivery typically takes between 1-7 days, depending on your location. - Q: What payment methods do you accept?

A: We accept L/C, T/T, Western Union, Cash, and PayPal.

Other Products

EVER-POWER GROUP offers a wide range of industrial products including agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, roller chains, pulleys and sheaves, planetary gearboxes, timing pulleys, bushings, and more. Our products are known for their superior quality, competitive pricing, and exceptional service. We welcome customers to provide drawings and samples for customization.

All the content of the page is from the Internet, the content is only as a reference for product selection, our products are replacement parts and not original spare parts; we are not the holder of the original trademarks of the content, our products are only suitable for after-sales replacement parts and not original spare parts, our replacement parts can be perfectly adapted to the original spare parts; if you need to buy original spare parts, please contact the original factory to buy. If you want to buy original spare parts, please contact the original supplier for purchase.

Performance Characteristics of CV Joint

Constant Velocity (CV) joints are crucial components in automotive drivetrains, providing seamless power transfer while allowing for a wide range of motion. These joints perform exceptionally well due to their unique attributes:

- Smooth Power Transmission: CV joints ensure uniform power delivery to the wheels, reducing vibrations and increasing vehicle stability.

- High Durability: Made from robust materials, CV joints can withstand substantial stress and wear, ensuring long-term reliability.

- Flexibility: These joints allow for the necessary flexibility in the drivetrain, accommodating the up and down movements of the suspension.

- Maintenance Requirements: Regular inspection and lubrication can significantly prolong the life of CV joints, minimizing the need for frequent replacements.

Types and Characteristics of CV Joint

There are primarily two types of CV joints:

- Rzeppa Joints: Often used in front-wheel-drive vehicles, these joints provide a constant velocity ratio and are highly efficient at extreme angles.

- Tripod Joints: These are typically found at the inboard end of drive shafts and are designed to handle axial motion smoothly.

The material composition of CV joints also varies, impacting their performance and characteristics:

- Steel CV Joints: Known for their high strength and durability, steel CV joints are ideal for heavy-duty applications.

- Composite CV Joints: Lighter than steel, composite materials offer enhanced fuel efficiency without compromising performance.

- Chromoly CV Joints: These provide superior strength and resistance to wear, making them suitable for high-performance vehicles.

Application of CV Joint in Various Fields

The versatility of CV joints makes them indispensable in various fields:

- Automotive Industry: CV joints are critical in both front-wheel and rear-wheel drive vehicles, ensuring efficient power transfer and smooth operation.

- Industrial Machinery: In industrial applications, CV joints help transmit power in machinery that requires a high degree of flexibility and precision.

- Aerospace: CV joints are used in aircraft control systems, providing the necessary flexibility for complex movements.

- Marine Equipment: These joints ensure reliable power transmission in boats and ships, accommodating the movements of marine propulsion systems.

- Agricultural Equipment: In tractors and other farm machinery, CV joints accommodate the uneven terrain and dynamic movements, enhancing operational efficiency.

Future Development Trends and Opportunities for CV Joint Products

The advancement of CV joint technology is driven by the demand for better performance and sustainability:

- Material Innovation: The development of new materials, such as advanced composites and high-strength alloys, is expected to enhance the durability and efficiency of CV joints.

- Electrification: With the rise of electric vehicles, CV joints are being designed to handle the unique torque characteristics of electric drivetrains.

- Advanced Manufacturing Techniques: Techniques like 3D printing are enabling more precise and cost-effective production of CV joints.

- Sustainability: There is a growing focus on developing CV joints that are more environmentally friendly, through the use of recyclable materials and energy-efficient manufacturing processes.

How to Choose a Suitable CV Joint

Selecting the right CV joint involves several critical factors:

- Determine Application Requirements: Understand the specific needs of your application, including the type of vehicle or machinery.

- Evaluating Power Requirements: Ensure that the CV joint can handle the power output of your engine or motor.

- Check Speed and Torque Specifications: Verify that the joint meets the necessary speed and torque ratings for your application.

- Measuring the Length of the Shaft: Accurate measurements ensure proper fitment and optimal performance.

- Evaluate Connection Type: Ensure the CV joint is compatible with your existing drivetrain connections.

- Check Safety Features: Look for joints that offer additional safety features to protect against failure in extreme conditions.

Summary

CV joints play a pivotal role in the efficient operation of various mechanical systems, from automotive to industrial machinery. Understanding their performance characteristics, types, applications, and future trends can help in selecting the right CV joint for your needs. By considering factors such as application requirements, power, speed, torque, and safety features, you can ensure optimal performance and longevity of your CV joint.

Author: Dream